|

Automatic Heat/Cold Cutting and Sewing MachineThis machine is suitable for normal bag, normal printing bag and lamination PP woven bag.

|

|

Automatic Cold Cutting and Sewing Machine for PP Lamination PP Woven BagWith Automatic loading, EPC, cutting, sewing, side hol puching and handle punching PLC controlled, Delta touch screen, servo motor and push bag by mechanical arm.

|

|

Automatic Cutting and Sewing Machine with PE linerLED display monitors various data in the room to ensure air health

|

The Automatic Heat Cutting and Sewing Machine is a high-quality machine that can do many functions such as cutting, sewing, and pressing. This machine has many features that make it an excellent choice for those who need a reliable and efficient machine. These features include: a straight stitch function, automatic thread cutter, and a wide range of fabric types that can be sewn. Below is the Included Device in our Auto.Heat Cutting and Sewing Machine:

| ✔ Edge Position Controller | ✔ Voltage Protection Relay |

| ✔ Servo Control System | ✔ Heat Cutting Knife and Cold Cutting Knife for Woven Fabric |

| ✔ Auto. Sewing Thread-Breaking Alarm Unit | ✔ Heat Sealing Knife and Cold Cutting Knife for PE Film. |

| ✔ Bag Mouth Opening Device | ✔ Printing Mark Sensor |

| ✔ 5 HP Air Compressor |

Automatic Heat Cutting and Sewing Machine is the latest innovation in sewing machines. It is a unique machine that allows you to do both auto.cutting and sewing at the same time. This saves you time and money because you no longer have to switch between the two functions.FOR MORE DETAIL PLEASE VISIT OUR WEBSIDE

|

|

FACTORY ENVIRONMENT |

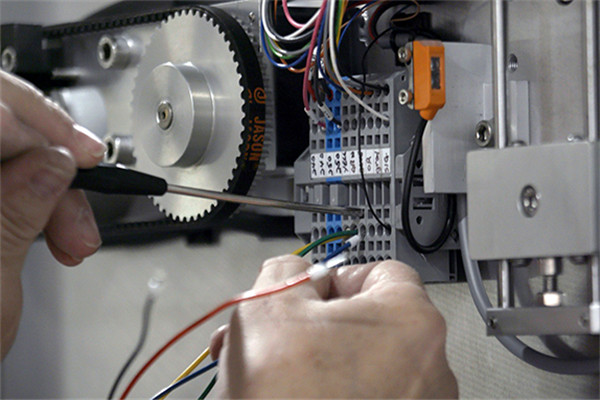

EQUIPMENT MANUFACTURING |

|

|

|

DEBUG INSTALLATION |

Customers gain insight into the product |

Offoce environment |

|

|

Packaging Design & Development |

Custom Machine Engineering |

|

|

|

Integration |

Retrofitting & Customizing |

Installation/Validation |

Provide all kinds of high-quality cutting machine accessories and provide other brand cutting machine repair, recycling and upgrading services

|

|

|

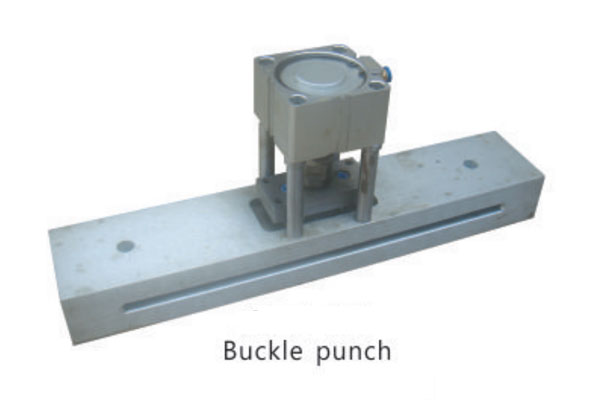

Buckle punch |

Color standard sensor |

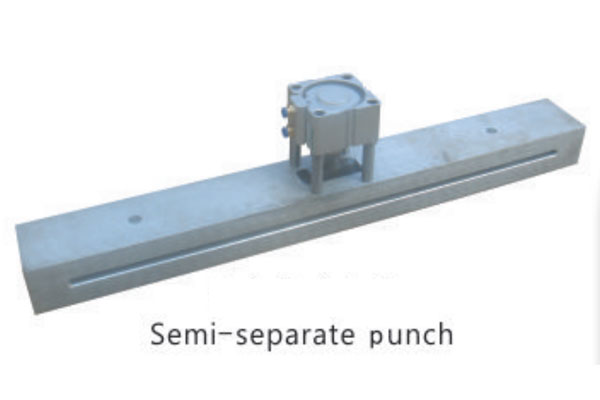

Semi separated punch |

|

Easily remove buckles without damaging fabric |

The sensor is very accurate and keeps the colors consistent across different fabrics. |

Semi-separated punch prevents fabric from getting tangled |

|

|

|

Sensor motor |

X-Eliminato |

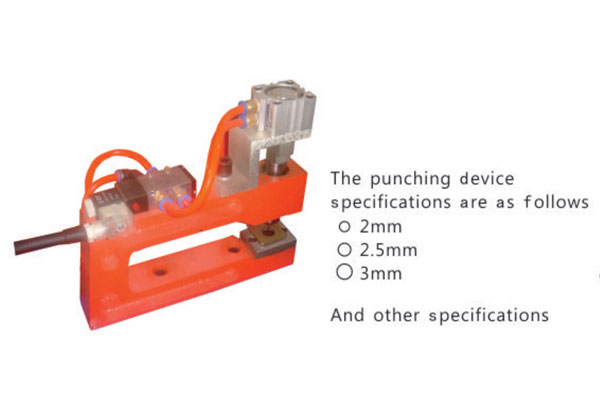

Punch |

|

Detects fabric type and weight |

The simple, one-button control makes it easy to sew fabric evenly and with precision. |

Punch creates even, precise cuts every time |

Cut and Sewing Machines appeared, everyone must be very surprised. In the impression of many people, the sewing machine is already an old household machine, a memory of a generation. In the future, Cut and Sewing Machines will replace traditional sewing machines and continue to play an important role in people's lives. Today, bigLet's learn about Cut and Sewing Machines together.

The China cut and sew machines factory is a type of manufacturing facility where various garments and textile products are produced. The products made in this type of facility can range from simple items like t-shirts to more complicated items like wedding gowns. The China cut and sew machines factory usually has a large production floor with a variety of different machines that are used to create the final product.

A China cut and sew machines factory is a type of manufacturing facility where various types of machines are used to cut and sew fabric into clothing and other textile products. These China factories can vary greatly in size and scope, from small operations that only employ a handful of workers to large-scale facilities that employ hundreds or even thousands of workers. In most cases, the workers in these China factories are highly skilled and experienced in the use of the various machines involved in the production process.

A China cut and sewing machines factory is a facility where machines are used to cut and sew fabrics into finished products. The products produced in a China cut and sewing machines factory can range from clothing to upholstery. In order to operate a cut and sewing machines factory, workers must be trained in how to use the machines.

Use science and technology to transform traditional sewing machines, retain the basic functions of traditional sewing machines, integrate the latest intelligent electronic technology, and change the purely manual traditional sewing machines into new sewing machines that rely on electricity to automatically run. This is the Cut and Sewing Machines. Except for the transformation of the core part , The Cut and Sewing Machines has a greater improvement than the traditional sewing machine in terms of appearance, function, use, etc., more beautiful, more delicate and more practical.

There are many suppliers of cut and sewing machines, but not all are created equal. You want to make sure you find suppliers that is reliable, has good customer service, and offers a good selection of machines.

There are many suppliers of cut and sewing machines, but not all are created equal. Some offer lower prices, but at the expense of quality or service. Others may be more expensive, but offer better quality machines or better customer service. When choosing suppliers, it is important to consider all factors to ensure that you are getting the best possible value for your money.

The appearance is beautiful and fashionable, the body is small, and the installation is convenient, which is very suitable for modern family use. The combination of straight line sewing and curved sewing can take into account both ordinary sewing and overlocking; straight line double needle sewing, the stitches are firm and beautiful; bidirectional sewing enables both forward sewing and reverse sewing, and is easy to use.

Operational intelligence. Two kinds of switches, setting button and foot pedal, are convenient and flexible to operate; the sewing speed can be adjusted at will;

Warm details. The Cut and Sewing Machines is equipped with a light, which can be used in places with poor light; the setting of the protective plate can avoid the fingers being pierced during sewing, and the use is safer; the special winding setting is more convenient for winding; the operation diagram is printed on the body display for easy operation guidance; spool rewind function makes sewing faster. These little details make the electric sewing machine even more cosy.

A China cut and sewing machines manufacturer is a company that produces machines used in the cut and sew industry. This industry uses machines to cut and sew fabric into clothing and other textile products. Cut and sewing machine manufacturers typically produce a variety of machines designed for different purposes, such as cutting, sewing, pressing, and embroidering. Some companies also produce software that helps manage the production process.

A China cut and sew machine manufacturer produces machines that are used to cut and sew fabric. The machines may be used to cut patterns or to cut fabric for clothing. They may also be used to sew seams or to embroider fabrics. Cut and sew machine manufacturers typically sell their products through distributors or retailers.

A cut and sewing machine manufacturer is a company that produces machines used in the cut and sew industry. The China cut and sew industry is responsible for the production of clothing and other textile products. Cut and sew machine manufacturers produce a variety of machines, including those used for cutting fabric, sewing seams, and applying finishing touches to garments.

Some cut and sewing machine manufacturers also produce machines used in other industries, such as the automotive industry. These companies usually specialize in producing machines for a specific industry or application.

Cut and Sewing Machines are only suitable for home use due to the special settings on the body and functions, and are prohibited for commercial use, otherwise the sewing machine will not work properly and be easily damaged. The use of the Cut and Sewing Machine should be carried out strictly in accordance with the illustration. There are some places that need to be paid attention to. Let's take a look.

1. The two switches on the fuselage cannot be used at the same time, only one of them can be used.

2. The threading must be threaded from front to back, and the positions of the upper and lower thread cores must be correctly operated according to the operation diagram.

3. Harder fabrics and thicker fabrics cannot be sewn with this sewing machine, otherwise, the sewing machine will be easily damaged.

4. If you use a transformer, be sure to remove the battery.

5. It is forbidden to use rectifier and dry battery at the same time.

6. The battery must be installed correctly during use. The reverse of the positive and negative poles of the battery will cause the sewing machine to reverse, and the sewing machine will be damaged for a long time.

There are many cut and sewing machines wholesalers that can be found online. These wholesalers offer a wide variety of machines that can be used for a variety of purposes. Some of the machines that these wholesalers offer include: quilting machines, embroidery machines, sergers, and even industrial sewing machines. When looking for a cut and sewing machine wholesaler, it is important to find one that offers a wide variety of machines so that you can find the perfect one for your needs.

A cut and sew machine is a type of sewing machine that is used to create garments from fabric. Cut and sew machines come in a variety of sizes and styles, and can be used to create everything from simple clothing items to complex garments. Wholesalers of cut and sew machines typically sell their products to garment manufacturers, tailors, and other businesses that require this type of equipment.

There are many wholesale cut and sewing machines suppliers that provide machines to both businesses and individuals. The prices of the machines vary depending on the type and brand of machine. Many of the suppliers offer discounts for bulk purchases.

1. The power button and the foot pedal cannot be used at the same time;

2. The rectifier and dry battery cannot be used at the same time, and the simultaneous use will cause damage to the machine;

3. When the positive and negative poles of the battery are wrong, the machine will be reversed, and sewing will not be possible when the machine is reversed;

4. Continuously reversing the machine for a long time will damage the machine;

5. This machine cannot be used for fabrics that are too hard and too thick.

A China cut and sewing machines factory is a type of manufacturing facility where machines are used to cut and sew fabric into finished products. These China factories can produce a wide variety of products, including clothing, upholstery, and linens. In order to operate effectively, these China factories require a variety of different types of machines, including cutting machines, sewing machines, and pressing machines.

A China cut and sewing machines factory is a type of manufacturing facility where machines are used to cut and sew fabrics together to create garments. These China factories can be small, family-owned businesses or large, multinational corporations. The China cut and sewing machines factory industry is an important part of the global textile and clothing sector.

Sewing tools have also undergone many changes. It has developed and is an electric sewing machine. The electric sewing machine not only saves a lot of manpower, but also is more delicate in some workmanship. However, how to use an electric sewing machine? What are the components of an electric sewing machine? After understanding its composition, you will have a better understanding of how it works. Now we will give you a detailed answer.

A China cutting and sewing machine factory is a type of manufacturing facility that produces machines used in the cutting and sewing of fabrics. These China factories usually produce a variety of different machines, each designed for a specific purpose. The most common type of machine produced by a China cutting and sewing machine factory is the sewing machine. Other types of machines produced by these China factories include cutting machines, pressing machines, and embroidery machines.

A China cutting and sewing machine factory is a manufacturing facility where machines are used to cut and sew fabric into clothing or other textile products. These China factories can be small, family-owned businesses or large, multinational corporations. The machines used in these facilities vary depending on the type of product being produced. Some common machines found in China cutting and sewing machine factories include fabric cutting machines, sewing machines, and embroidery machines.

A China cutting and sewing machine factory is a type of manufacturing facility that produces machines used in the cutting and sewing industry. These China factories may produce a variety of different machines, including those used for cutting fabric, sewing garments, and performing other related tasks. In some cases, a single China factory may produce all types of machines needed for the industry, while in others each type of machine may be produced by a different facility. Generally, the machines produced by these China factories are designed for use in commercial settings such as garment factories or textile mills.

1. The winding sequence of the upper thread and the placement of the bottom thread core must be correct (as shown in the manual), otherwise the sewing machine will not work normally;

2. When threading the needle, the threading direction must be correct (from front to back), otherwise it will not be able to sew normally;

3. Do not use the foot pedal switch and the power button at the same time;

4. Please take out the battery when using the transformer.

A cutting and sewing machine supplier is a company that manufactures and distributes machines used for cutting and sewing fabric. These machines are used in a variety of industries, including the clothing and textile industries. Cutting and sewing machine suppliers typically offer a wide range of machines, from simple to complex, to meet the needs of their customers. Some suppliers also offer training on how to use their machines.

When it comes to finding a cutting and sewing machine supplier, you want to make sure you find a reputable one. There are a few things you can do to help ensure you find a good supplier. First, ask around for recommendations. Talk to people in your network who have experience with cutting and sewing machines, and see if they have any recommendations.

Second, do some research online. Look for online reviews of potential suppliers. Finally, once you've found a few potential suppliers, get in touch with them and ask questions about their products and services. By taking these steps, you can be confident that you're finding a good cutting and sewing machine supplier.

A sewing machine is a machine that uses one or more sewing threads to form one or more stitches on the sewing material, so that one or more layers of sewing material are interlaced or sewn together. The sewing machine can sew cotton, linen, silk, wool, man-made fibers and other fabrics and leather, plastic, paper and other products.

There are many classification methods of sewing machines, and the most common is to distinguish them according to stitches and uses. The stitches of sewing machines can be classified into two categories: lock stitches and chain stitches. The lock stitch is the most common and consists of two stitches intertwined like a twisted rope, with the interlacing point in the middle of the seam material. From the cross-section of the stitch, the two stitches are like two locks locked to each other, so they are called lock stitches. This stitch is used for sewing materials such as cotton, wool or leather with low shrinkage. The front and back sides have the same shape, like a dotted line. The stitches are densely distributed, and the sewing fastness generally exceeds that of manual sewing.

Chain stitches are self-connected or interconnected by loops of sutures. Commonly used are single-thread chain stitches, double-thread chain stitches and three-thread overlock stitches. The characteristic of this stitch is that the stitch is elastic, and it can expand and contract with the sewing material without breaking the stitching.

A cutting and sewing machine wholsaler is a company that specializes in the sale of cutting and sewing machines. These machines are used to cut fabric and sew it together to create clothing and other items. Cutting and sewing machine wholesalers typically sell their products to garment manufacturers, clothing retailers, and other businesses that use these machines in their operations. Many cutting and sewing machine wholesalers also sell other types of textile machinery, such as knitting machines and embroidery machines.

A cutting and sewing machine wholesaler is a company that provides cutting and sewing machines to businesses that resell them to consumers. These wholesalers typically sell their products through distributors or directly to retailers. Some also offer online sales. The most common type of cutting and sewing machine wholesaler is a manufacturer's representative, which is an agent that represents one or more manufacturers of cutting and sewing machines.

The machine head is the main part of the sewing machine. It is composed of four mechanisms: barbed material, hook thread, thread take-up and feeding mechanism, and auxiliary mechanisms such as thread winding, material pressing, and tooth dropping.

The base is divided into two forms: platen and chassis. The platen of the table-type machine base plays the role of supporting the machine head and is used as a workbench during sewing operations. There are many styles of tabletops, such as one-bucket or multi-bucket folding Tibetan type, cabinet type, writing table and so on. The chassis of the chassis-type machine base plays the role of supporting and storing the machine head, making the sewing machine easy to carry and store.

The transmission part of the sewing machine is composed of parts such as a frame, a hand crank or a motor. The frame is the backbone of the machine, supporting the deck and footrests. When in use, the operator steps on the pedal, drives the rotation of the pulley through the crank, and drives the head to rotate through the belt. Most hand cranks or motors are directly mounted on the nose. Sewing machine accessories include needles, bobbins, knives, oilers, etc.

A cutting and sewing machine producer is a company that manufactures machines used to cut and sew fabric. These machines are used in a variety of industries, including the clothing industry, the automotive industry, and the aerospace industry. Cutting and sewing machine producers typically offer a wide range of machines, from simple to complex, to meet the needs of their customers. Many cutting and sewing machine producers also offer training on how to use their machines.

A cutting and sewing machine producer is a company that manufactures machines used in the cutting and sewing of fabrics. These machines are used in a variety of industries, including the clothing, automotive, and upholstery industries. Cutting and sewing machine producers typically offer a wide range of machines to meet the needs of their customers. Some of the most popular types of machines produced by these producers include rotary cutting machines, straight stitch machines, zigzag stitch machines, and buttonhole machines.

Cutting and sewing machine producers are responsible for the design, manufacture, and distribution of machines used in the cutting and sewing of textile fabrics. Producer may also be involved in the research and development of new cutting and sewing technologies, as well as the marketing of these technologies to potential customers. Cutting and sewing machine producers typically work in close collaboration with other members of the textile manufacturing industry, such as fabric producers and garment manufacturers.

Reason analysis: The shuttle bed, shuttle, bobbin case and bobbin of the cutting and sewing machine are under the cutting and sewing machine, and they are interlocked layer by layer. The most prone to failure is the shuttle, which has a point in front of it. Over time, this point will become bald, and the needle will skip and the thread will break.

Solution: Change the shuttle.

In a cutting and sewing machine China factory the machines are used to cut and sew fabrics. The workers operate the machines and oversee the production process. The finished products are then shipped to retailers.

A cutting and sewing machine China factory is a type of manufacturing facility where machines that are used to cut and sew fabric are produced. These facilities can be small medium or large in size and they may be located in any country around the world. The machines produced in these China factories are used in a variety of industries including the clothing industry the automotive industry and the furniture industry.

Reason analysis: The function of the bobbin case is to adjust the upper and lower lines. If the upper and lower lines are not symmetrical, it means that there is a problem with the screws of the bobbin case.

Solution: Tighten the screw or loosen the screw.

If you are looking for a cutting and sewing machine ODM and OEM supplier you have come to the right place. We offer a wide variety of machines that are perfect for any project. Whether you need a heavy-duty machine for commercial use or a lightweight machine for home use we have the perfect option for you. We also offer a variety of accessories and replacement parts so you can keep your machine running smoothly. Contact us today to find the perfect cutting and sewing machine for your needs.

The cutting and sewing machine supplier is a great resource for those who are looking for a new machine. They offer a wide variety of machines from simple to complex and can help you find the perfect one for your needs. They also offer a variety of accessories like cutting mats and foot pedals to make your sewing experience even better.

Reason analysis: The needle handle on the needle is flat, and there is a needle eye below. The needle handle of a good quality machine needle is perpendicular to the needle eye, and the poor quality is not perpendicular. The first thing to do is to choose a good quality needle. If the needle is reversed or not in place, the thread will not hang up.

Solution: The correct way to install the needle is to have the needle groove on the needle to the left. When installing the needle, it should be pushed up to the end.

If you're looking for a cutting and sewing machine wholesaler there are a few things you should keep in mind. First you'll want to find a reputable supplier who can provide you with high-quality machines. Second you'll need to decide what type of machines you need. Third you'll want to compare prices and find the best deals. By following these tips you can be sure to find the perfect cutting and sewing machine wholesaler for your needs.

A cutting and sewing machine wholesaler is a company that sells machines used for cutting and sewing fabrics. These machines are used in a variety of industries including the clothing footwear and upholstery industries. Cutting and sewing machine wholesalers typically sell their products to manufacturers retailers and other businesses that use these machines in their operations.

Reason analysis: The cutting and sewing machine has a special cutting and sewing machine oil. Under normal circumstances, the cutting and sewing machine oil is transparent, and it will turn yellow after a long time, but it can be used. The oil many people use is not cutting and sewing machine oil, but edible oil, transformer oil, etc. These oils are viscous and will make the machine unable to rotate for a long time. Although some people use cutting and sewing machine oil, when they put the oil in the beverage bottle, the viscosity of the oil will increase due to the sugar on the bottle wall, making the cutting and sewing machine unable to rotate.

Solution: disassemble the parts and clean with oil.

An electric sewing machine manufacturer produces machines that sew fabrics together using an electric motor. The manufacturer may also produce other types of sewing machines such as those that use a foot pedal or those that are operated by hand. In some cases the electric sewing machine manufacturer also produces the fabric that is used in the construction of the machines.

Electric sewing machines were first introduced in the late 19th century and quickly became popular among seamstresses and tailors. Today there are many different manufacturers of electric sewing machines each with their own unique features.

Reason analysis: The leather belt of the cutting and sewing machine is loose.

Solution: You need to tighten it or replace it. And the way to maintain the belt is to regularly oil it, don't let it dry.

Wenzhou Yiran Import & Export Co., Ltd. is based in Wenzhou, China,with more than 15 years experiences of plastic machinery that offers machines to clients at reasonable prices and best service.

Expansion of the infrastructure by installing latest machines for printing, slitting, packing along with continuous development keeps us at the forefront of the industry. We are a technology advanced and customer led company, focused to meet clients expectations by offering exact products as per their requirements.