Manufacturer/Factory/Supplier in China

YIRAN has a long history of producing high-quality machines that are widely used in the industry.

YIRAN is one of the leading PP woven machine suppliers factory in China. With years of experience and rich resources, we can provide you with the best quality PP woven machines at competitive prices. Our experienced engineers are always ready to offer you customized solutions for your specific needs.

The PP woven machine is a new and innovative way to create textile products. It uses a two-dimensional mesh fabric to create textiles with a unique pattern. The machine is relatively small and easy to use, making it a great option for small businesses.

The PP woven machine is a unique and efficient way to produce fabric. This machine uses a series of parallel bars to create a fabric that is highly durable and perfect for many applications.

PP woven machine products are used to create products from a variety of materials, including paper, plastic films, and textiles. The machines can produce a variety of fabrics, including lightweight and strong fabrics. They are also versatile and can be used to create a wide range of products.

Full Automatic PP Value Bags Making Machine is the latest innovation in the world of packaging. This machine is capable of manufacturing high-quality, full automatic PP value bags at a much faster pace than manual methods. This machine not only saves time and labor, but also produces higher quality bags that are less likely to tear or rip.

Automatic value bag making machines are becoming popular for a variety of reasons. First, there is no need to handle the bags and secondly, the machines can produce a lot of bags in a short amount of time. The machines vary in price, but they are all fairly affordable.

China (Normal) Leno & Mesh Bags Making Machine is used to make the Leno and Mesh bags. This machine can produce a variety of shapes, sizes, and colors of bags. It has a number of features that make it easy to operate. The machine is also fast and efficient, making it a great choice for businesses that need to produce a lot of bags quickly.

China (Normal) Leno & Mesh Bags Making Machine has the following features: large capacity, high speed, low noise, and smooth operation. Apart from mesh bags, it can also be used to make other types of bags, such as cloth bags, paper bags, and so on. Thanks to its versatile function, this machine has been widely used in various industries.

1.In recent years, there has been a growing demand for eco-friendly products. One way to reduce the environmental impact of products is to produce them using sustainable manufacturing methods. One such method is HDPE woven sack bag making machine, which is a low-cost, efficient way to make sacks from HDPE materials.

2.This machine uses a simple weaving process to create sacks from HDPE material.

A bag making machine is a great invention that makes it much easier and faster to create bags. This machine uses a series of rolls to produce the desired shape, which eliminates the need for hand sewing. The machine is also very easy to use, making it an ideal choice for those who are not experienced in the art of bagmaking.

Bag Making Machine: A Machine That Makes Customized Bags

Looking for a unique and personalized gift? Check out a bag making machine! These machines can create any kind of bag you can imagine, from simple totes to elaborate purses. Plus, they're perfect for customizing any existing bag or creating your very own design. So if you're in the market for a special gift, be sure to check out a bag making machine!

Woven fabrics are a popular choice for clothing, but they can be expensive to produce. Pp Non Woven Machine is a machine that creates fabrics from non-woven materials. It is a low-cost option for creating lightweight fabric products.

PP non woven machine is a kind of specialized machine that can be used to produce various types of PP products. This machine has a lot of advantages, such as high production efficiency and low production costs. It is also very versatile, which makes it perfect for producing a variety of different types of PP products.

PP woven machine is a kind of weaving machine that can produce various types of fabrics like T-shirt, jeans, sweatshirt and so on. The machine has the following components: spinner, loom, beam and shuttle. Let's learn how to operate PP woven machine in this guide.

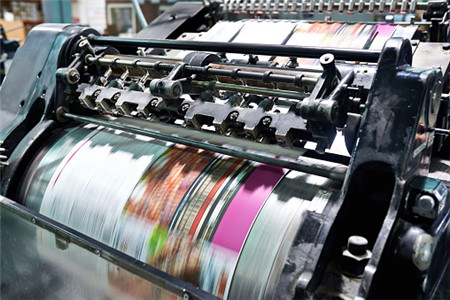

Powder-paint-printing (PP) woven fabric production line is a new type of industrial weaving equipment which has been widely used in recent years. PP woven fabric production line mainly consists of a control room, weaving machine room, painting machine room, and other auxiliary rooms. The control room is the main control center of PP woven fabric production line, and it controls all the functions of the other rooms.

| ✔ Precision- Made with high quality parts, this machine produces bags of consistent and accurate PP value. | ✔ Fast- It can produce bags in just a few minutes, making it fast and easy to produce a lot of bags. |

| ✔ Cost-effective- Compared to other machines on the market, this one is much cheaper and easier to operate. | ✔ Versatile- This machine can be used for a variety of different purposes, such as packaging products or making custom bags. |

The PP woven machine is a type of weaving machine that uses a punched paperboard cylinder to create textiles. In order to operate this machine, you will first need to load the fabric into the cylinder and then set the tension on the loom. Once the tension is set, you can start weaving the fabric and then remove it from the loom when finished.

If you own a PP woven machine, there are some simple tips that you can follow to keep it running smoothly.There are some simple maintenance tips you can follow to keep your PP woven machine in top condition:

-Clean the weaving area regularly with a damp cloth to remove any built-up debris.

-Wash the machine regularly with cool water and a mild detergent.

-Check for frayed or broken cords, and replace as needed.

-Check the belts for wear and replace as needed.

-Clean the spinning wheels with a brush and solvent every few months.

-Check the tension on the warp and weft threads regularly and adjust as necessary.

-Rotate the spools of yarn regularly to avoid tangles.

|

|

Medical equipment |

Packaging |

|

|

|

Automobile industry |

Aerospace |

Electrical industries |

The bag making machine is specially designed as a dual-purpose machine for point-disconnected and continuous-rolling flat pockets and point-disconnecting and continuous-rolling vest bags. Using computer control, the step (servo) fixed-length system makes the sealing and cutting size error small. The device electric eye tracking makes the pattern position of the printed bag accurate. The length of the bag can be adjusted by computer numerical control. If there is a problem with the printing bag, the machine will automatically stop and give a warning sound. Let's learn the operation process of the bag making machine:

1. Check whether there is dust and debris around the equipment and remove them.

2. Install the film roll according to the requirements of the production notice.

3. Adjust the size of the bag according to the production notice and process documents, install the heat sealing knife, and preliminarily adjust the position of the slitting knife and the heat sealing knife.

4. Turn on the power and set the temperature of the heat sealing knife according to the requirements of the process document.

5. Input the relevant data of bag making and the required number of each bundle.

6. Select the edge of the pattern with large color difference and adjust the sensitivity of the light eye to make it meet the requirements.

1. Start the main motor, run at low speed, and then adjust the edge position control to divide the film in the middle position.

2. Adjust the left and right pinch rollers to align the left and right films, and adjust the front and rear pinch rollers to align the pattern.

3. Adjust the heat-sealing knife to make it heat-sealed within the required range of the bag.

4. Adjust the slitting blade to the desired position, and adjust the punching position to the scissors mouth.

5. Preliminarily adjust the speed of the machine, take a flat-out sample bag for initial inspection, and if it does not meet the specified requirements, take another flat-out sample bag for heat sealing value test.

6. Arrange the produced bags, and select the bags with quality defects (such as folding, tunnel, flower width, knife line, poor heat sealing, four seals, etc.) and bundle them according to regulations.

7. The machine quality inspector will carry out the inspection. After the inspection is qualified, the certificate will be pasted and sent to the quality inspection room for random inspection.

8. During the production process, observe the bag making situation at any time and find any abnormality and adjust it immediately.

1. Disconnect the main power switch, and then disconnect the power switch of each part.

2. Clean the machine hygiene and site hygiene, and send the products to the general inspection room.

3. Make a record of the shift, requiring accuracy and cleanliness

1. Packing: The machine personnel will sort out the products in this process, select the unqualified products with quality defects (such as folding, tunnel, flower width, cutting line, poor heat sealing, four seals, incomplete patterns, etc.) The product is bundled and handed over to the machine quality inspector for inspection.

2. Inspection: The quality inspector of the machine will inspect the quantity and quality one by one. After the quantity and quality are all qualified, they will be put into the box according to the requirements and put into the packing list; Qualified" marked in the carton.

3. The machine personnel will send the products on duty to the appearance quality inspection room.

4. The general quality inspector will sample and inspect the products submitted for inspection according to the specified proportion, and pack them into storage after passing the inspection.

Wenzhou Yiran Import & Export Co., Ltd. is based in Wenzhou, China,with more than 15 years experiences of plastic machinery that offers machines to clients at reasonable prices and best service.

Expansion of the infrastructure by installing latest machines for printing, slitting, packing along with continuous development keeps us at the forefront of the industry. We are a technology advanced and customer led company, focused to meet clients expectations by offering exact products as per their requirements.