Application guide about fabric cutting machine

Rotary machines are generally less expensive than laser machines, but they can be more difficult to use. Laser machines are more expensive, but they offer a more precise cut and are easier to use.

When choosing a fabric cutting machine, you will also need to decide on the size that you need. Fabric cutting machines come in a variety of sizes, so it is important to choose one that is large enough to accommodate your project.

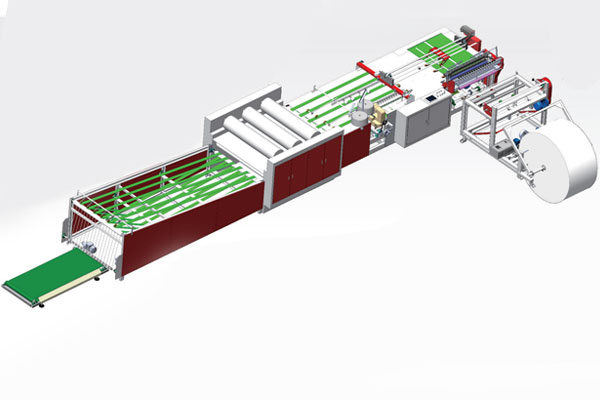

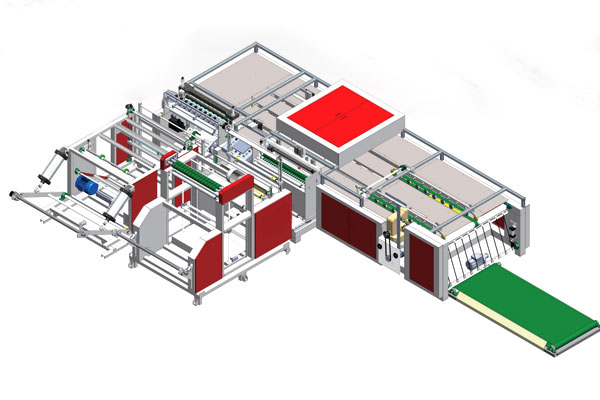

Automated fabric cutting machines are an essential part of any textile business, whether you make clothes, curtains, or upholstery. With these machines, you can quickly and efficiently cut fabric to the desired shape and size, which saves time and money.

How efficient is the fabric cutting machine?

The world of textile manufacturing can be a fast-paced and demanding environment, where every second of production time counts. That's why fabrication companies around the globe are investing in the latest technology to improve efficiency and productivity. One such machine gaining popularity is the fabric cutting machine, which uses advanced computer software to precisely cut fabrics to size. When it comes to efficiency, this high-tech tool offers a range of benefits. Not only does it reduce waste and save time, but it also ensures accuracy and consistency in the production process. In short, the fabric cutting machine is a game-changer for the textile industry, making it faster and more efficient than ever before.

What is the production cost and selling price of fabric cutting machine?

Fabric cutting machines are a valuable addition to the textile industry, but many people may wonder about their production cost and selling price. While the exact figures may vary depending on the manufacturer, type of machine, and other factors, it is safe to say that these machines can be a significant investment. However, the benefits of having precise, efficient cutting capabilities can pay off in the long run. When considering the cost and potential return on investment, it is important to research and compare options to find the right fabric cutting machine for your specific needs.